| |

| Preserving our Natural Resources since 1997 | Your browser can't find the .css style script |

| Home | Equipment | Projects | Contacts | Links | About Us | |

|

Helga The Horrible!Well that's what we call her. In the Summer of 2000, we bought our very own Northwest 25 crane. She is 50 years old and weighs in at over 25 tons, but don't tell her I told you that!She has a 4 cylinder diesel engine and a 5/8 yard bucket. Don't let her size bother you, she has a great personality! |

| A closer shot of the cab, the cables look good. Most everything works, except the boom hoist that we fixed. We got another almost complete crane as spare parts too. |  |

|

We had her trucked up north on a lowboy trailer by Ed from CMA Heavyhaul After Helga was off Ed's lowboy, we started unloading the spare parts truck |

| We also got some old wooden crane mats to stand on when the ground is soft. We'll use these! |  |

|

The guts of another machine for spare parts. It has everything except for an engine and the cab. |

| Someone spend quite a bit of time working on the old girl. Everything works fine except the boom hoist! I can't believe all of the moving parts are right next to the operator! I'd better be careful. |  |

|

A look at the Murphy diesel, a huge 4 cylinder engine. |

| The power assist bands for the lift and drag clutches are right behind the operator. Be careful where you lean your elbow! |  |

|

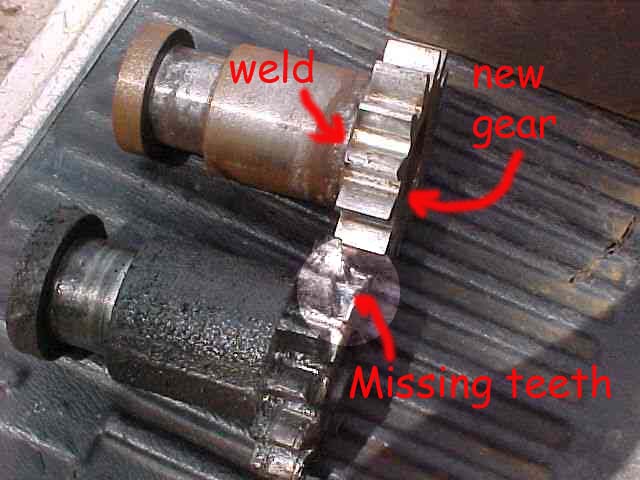

The only real problem we've had so far was a broken boom hoist. We rebuilt a gear from the broken spare part we had.

We removed the broken teeth down to the shoulder, then made a new gear blank ourselves. We then sent the ring out to have teeth hobbed onto the "doughnut". |

| Just like we thought, missing teeth on the old (bottom) gear. Now to get the new gear installed! |  |

|

We had to take the side of the crane off, other than rusty bolts it wasn't too bad. The new gear fixed the boom hoist problem! |

|

The next problem we ran into was the lift clutch lining was worn out.

We took the spare lining in for repair. That was easy enough, but to get the old one out, and the new one in was a chore! |

|

|

What a job, we finally figured out how it's done after half the day was gone! |

|

Back together and working better than ever!

Helga loves to work with Dumpy. They make a great team for moving material around. |

|

| back to the top

Here's a bit of a story about Helga. Click on the blue text to popup a picture or follow a link. In the summer of 2000 we decided that we needed a way to lift our dredge out of the water in the coming winter We also needed to dig some dirt too, so we started looking for a dragline We checked "Equipment Trader Online" to see what was available. We found only a few for sale, and only 1 was in our price range! and it was only 10 miles from the house! .....destiny? We went to look at her, she was beautiful, with 70 feet of boom and a 4 cylinder Murphy diesel. After some intense haggling with the owner,we sealed the deal. Then we needed a ride for her and the 10 tons of spare parts that where included. We found that CMA Heavyhaul had 2 trucks that could do the job, so in early August we loaded up everything and headed north! Ed from CMA was driving Helga on his lowboy when he went through the scales in Bay City. He was 2,000 Lbs over weight. We had permitted for an over length load, but if we moved her back, we would be over length, so we called a local repair truck to help us take out a 10 foot section of the boom, right in the weight station parking lot! AHHHH, 2 hours on the clock!!!! Back on the road finally, we arrived at the Bloom Lake and tried to raise the boom to unload the old girl, that's when we found that the boom hoist didn't work, what a time to find that out, with 2 truck drivers (again, on the clock) watching me struggle with her. Ed finally got the boom up , then we unloaded the spare machine off of the other truck with Helga. What a trip! When we got home, we contacted a distributor of parts for the now defunct Northwest Engineering Co. We learned that the gear we needed was close to $1,800, that is about 25% of the cost of the machine! We rummaged through the 2 tons of small spare parts in the barn, I found the gear we needed! It had teeth missing too. So with a spare part to work on, I could start fixing the spare, then do an exchange, good idea. But, as I soon found out, Northwest Engineering used special non-standard gear cutters, so that you have to buy spare parts from them. I called everyone that I could to try to find the correct gear tooth design and diameter ratio, I did learn a lot about gear jargon, and about gear geometry's so it was a good experience. I finally found a person at Crane Specialist, who took pity on a poor (cheap) soul, and faxed me a drawing of the gear. Armed with this information, I searched out a local company that makes gears. To keep the cost down I bought the steel, and on a lathe, turned the gear blank (it looks like a steel doughnut). I made a mandrel and pressed it through the open center of the gear casting, I used the lathe to remove all of the teeth and make a shoulder for the doughnut to press onto, then I had them cut the closest standard gear to the non-standard original. Then I welded the new gear to the old housing. So $30 for the steel, $90 for the gear machining, and a few hours of my time, was easily less than the $1,800 cost of the replacement part. Now the test, would it fit (and work?). To install the gear, I had to lower the boom, something that takes hours to raise without the boom hoist working, I pulled the side of the machine off to make room for me, it is very tight in there, and removed all of the stuff in the way. After about 2 hours of work, I removed the old gear. It had missing teeth too (that's good) I cleaned everything up and put her back together with the repaired gear, fired the engine up, It worked! the boom hoist raised the boom just like it should. Yahoooooo. Then in July of 2001 we had to replace the lift clutch that went out. It finally got so bad we couldn't lift the empty bucket! this happened during the violation cleanup, bad timing!. We had a old shoe from the spare machine, so we took it home, cleaned it up and send it out to have a new lining put on, the reline was only $90 bucks! The clutch is in a very hard area to get at, it is behind a giant gear case and there is NO room to work. I thought we had to remove the cable, the lagging (cable drum), and the clutch/brake drum to get the clutch band out of the machine. I was very wrong, so after 2 hours of disassembly I still couldn't get it out! It kept bumping into a rivet that was holding the frame together. I found just that rivet was actually a carriage bolt, and by removing that bolt, allowed the band to just slip past! every other fastener in that assembly was a rivet, except for this one special bolt! With that done we reassembled her, adjusted the clutch and found that she worked like never before! Ready to dig! |

|