| |

| Preserving our Natural Resources since 1997 | Your browser can't find the .css style script |

| Home | Equipment | Projects | Contacts | Links | About Us | |

|

Hey look what we found! A 1976 John Deere 450C with a 6 way blade and root rake on the back! It runs good let's get it! |

|

We found it in the early spring of 1998, all caked with frozen mud. Later we learned that mud can hide serious track troubles.

Fortunately, we didn't have any troubles with the tracks, but buyer beware!

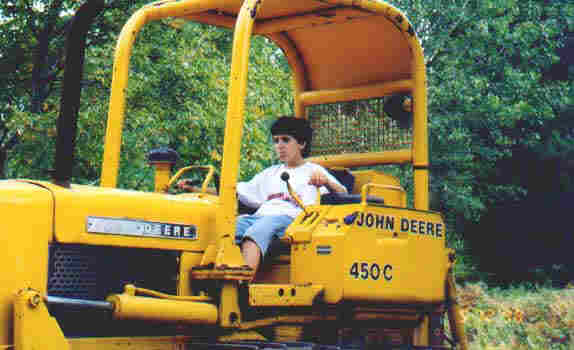

This is the controls view of our new dozer. Ever run one? not me, how do you start this thing...HELP! |

|

|

In August of 98, we finally got a ride from our new found truck driver. Ed works for CMA Heavy Haul, great service, good price! I gotta remember these guys! |

| This is a shot of Jenny driving the old girl. We had to fix up a few things. The turbo was shot so we replaced that. The seats where ripped, so we recovered them. The clutch is bad, I gotta fix that soon. |  |

|

Now it's Carol's turn |

| Even Mike gets a turn, he's pushing some of the dredge spoils around. |  |

|

During the summer of 2003, we worked the dozer pretty hard building

a road into the lake.

We noticed it was starting to use water, and the oil was milky with steam coming from the breather tube. We babied it along until the spring of 2004. After we pushed the dredge in the lake, we decided to tear it down and take the engine home. |

| It doesn't seem too bad, I plan to use Helga as the highpoint to attach a chainfall. |  |

|

A few bolts, hoses and linkages, and the engine was free! Helga worked great for lifting the engine, hydraulic pump and radiator assembly from the dozer chassis. |

| Once we got the assembly home, we removed the radiator and pump from the engine. The dozer manual said water consumption can be caused by a; leaky head gasket, cracked cylinder liners cracked head or block, or failed liner O-rings. Let's see what we can find! |  |

|

I stripped the engine of everything, and popped the head off looking for cracks and leaks. The head gasket and everything under it looked great, maybe a cracked block or head? |

| We had the cylinder head crack tested, it showed it was fine. While it was off, we had the valves and seats re-ground. |  |

|

The timing gear train looks fine. The idler bushings are a bit worn, so I'll replace those while I'm in there. |

| We had to build an engine stand, anything we could afford was too wimpy. |  |

|

The bottom end of the engine looked just dandy!

We popped the cylinder liners out, and found the source of the leaks! The liner packing and rubber O-rings had rotted away. We checked the crank and rod bearings, they where just about worn out, but not really that bad for a 28 year old engine. More to come! |

|

We ordered a "Reliance Parts Corp." major overhaul kit from AIS of Lansing. (Thanks Matt!) The kit contained everything needed to make the engine new again.

Carol was kind enough to let me work on the kitchen table when it came time to assemble the pistons, rings, connecting rods, and cylinder sleeves. The only thing left from the old engine was the connecting rods, and they got new bearings in both ends and new bearing cap bolts like the book calls for. |

|

|

Everything went together like a dream, all of the parts dropped in like the manual said they would.

The paint isn't the right color, the Deere dealer wanted $10 per can for the "Old Construction Equipment" yellow, so I painted it "New Construction Equipment" instead! The water pump gasket isn't included in the kit, I'm down for a few days until that shows up, so I'm painting everything as I go. |

|

Finally all of the assembly work is done. I adjusted the valves and bolted on the turbo,

connected the wiring and installed the filters.

The radiator and hydraulic pump bolted onto the assembly, so it's ready to fill with fluids, and take back north. The clutch disk was destroyed, the springs had exploded, that explains the clutch issue! Quality Clutch fixed us up with a replacement disk, and Deere sold us the pilot bearing. |

|

|

We filled the cooling system and pressure tested it to 15 psi. I added an anti-cavitation

additive to the coolant so I don't have the cylinder pitting issue again,

and pressure filled the lubrication system with 9 quarts of 10W-30.

We're on the trailer and waiting for a chance to head north! We're taking the lift with us to store in the barn, Helga is the tool of choice for the install. |

|

With Helga holding the chainfall, I slipped the engine in place. It didn't just "drop in" like

I had hoped.

I had the angle of the engine wrong, during a lunch break, I stepped back and noticed the problem. After I got that right, it slid right in with a problem. |

|

|

With everything bolted into place, now it's time crank the engine. It cranked and tried to start but the starter was beginning to smoke.

I finally got it to start, but I cut one of the coolant hoses on the way in, so I couldn't button up the front end yet. I took the starter home for rebuilding, if it's not one thing, it's another! |

|

July 4th, I installed the new starter, and it fired right up!

It smoked a bit, bet as it warmed up, the smoke cleared! I guess that might have been the assembly oil in the rings? I tried the clutch, that worked too! Now I need to re-assemble the front cowl. |

|

| back to the top

We finally bought some land, now we need a dozer to move dirt, so we checked "Equipment Trader Online" every Thursday when they updated the site. From others we learned we needed at least a 6 way blade and the more options the better. Then in spring of 1998 we found one that looked like it fit the requirements! Without knowing anything about any equipment, we bought it! It runs good, but the oil pressure is low at idle. We had it moved (by CMA Heavyhaul) to a RV storage yard near the house. We started by cleaning all of caked on mud from the tracks. Learning more about dozers, we found it to be in good shape with little wear on the undercarriage. Our inspection did find a turbo with a wiggly shaft bearing, we thought this was a $$ disaster! costing $1,000s, but we found that turbos' on diesel equipment are fairly cheap. A shop out in Lansing sent us one for less that $300. The oil line to the turbo was charred by the exhaust and the pressure sensor was in that line, so that fixed the low oil pressure and might be why the turbo died. The seat was badly ripped, so I bought some material and cut new sections and had a local shop sew them for me. Other than a few adjustment, some lube and cleaning she works great! One thing we did learn while we had the machine apart was.... if it's left in gear, and you hit the start button to look at the turbo spin, it will start...and it will move, and it's hard to catch and it's even harder to get inside to stop it! I screamed like a girl as it headed toward a large RV without me. By the end of August we had the work on the dozer behind us, we lined up a ride north with CMA again. We had little chance to move the machine around in the storage lot, so the driver ED, really got a laugh when I tried to load it on the truck. But 5 hours later it was up north, and we started pushing dirt! It's harder than it looks to push dirt. Flat ground becomes wavy ground until you learn the machine. And it doesn't care what's in the way, it will try to move it! It's been a great little machine, we all love it! All we need now is a barn to store it in! During the summer of 2003, I noticed the engine really spews a lot of steam from the breather The dozer has always run good, but but when pushed hard, it really went through the coolant! So in the spring of 04, before I had a major engine failure, I decided to get it home for some work. Old Helga worked good to hold our old chainfall. We plucked the engine right out, and took it home for an overhaul. I've never worked on engines, so I called Jasper for a price on an overhaul. They quoted $8,500 complete! OUCH! I called another place, and they wanted over $5,000, so it's time to learn about diesel engine repair, I think I can do it myself for a lot less. The gearheads at work assured me it wasn't that hard to do, they provided tools, advice, and moral support. Thanks to Ron & Bob for all the answers, and Rich for all the stuff he provided. The guys at Reliance Parts dug around and found a part number for a cheaper overhaul kit AP-206. The AP-206 pistons & rings are un-assembled, but it's $230 cheaper than the RP-206! More time than money, I always say. Matt at AIS in Lansing helped me order the right parts, and gave me a good deal too! The clutch never did work, now I know why. It looks like the clutch plate springs blew through their housing, and the pilot bearing was in tiny pieces. The flywheel and the pressure plate looked just fine. The Deere dealer wanted over $360 for a clutch plate, my dad turned me on to Quality Clutch in Westland, they had remans for $65, and the tested the pressure plate operation for free! With the head off, the valves needed a bit of attention. Most machine shops wanted $300 and up to work on my head. All it needed was a little touch-up on the seats and valves! Again, my dad suggested Mid-Five Auto, they did the crack check and clean-up for $70. All told, I think it was under $1,000 bucks total. |

|